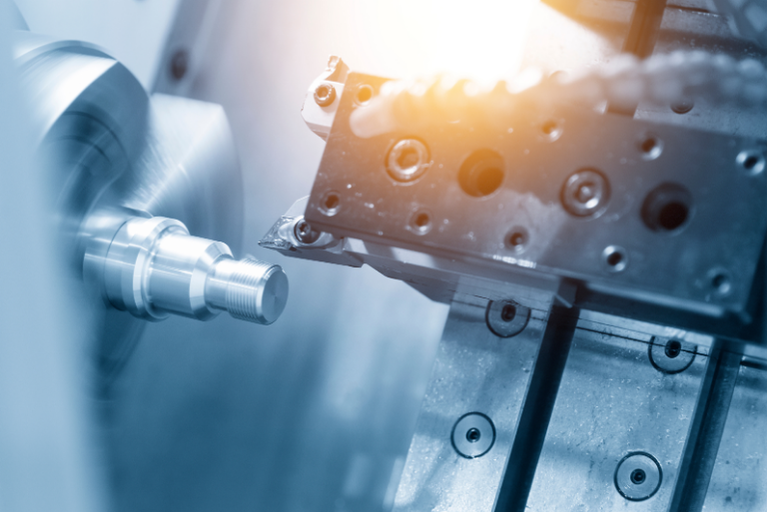

Through collaboration with numerous suppliers, we offer high-precision CNC turning services across a wide diameter range. Our capabilities include producing parts from 0.5 mm up to 1000 mm in diameter and up to 4000 mm in length, meeting all your turning needs. Our production processes are organized to ensure the best price and quality for our customers.

Wide Processing Capacity and Precision

From small precision parts to large-scale industrial components, we can produce a wide variety of workpieces with high precision. We offer the most suitable solutions to manufacture your parts with complex geometries and appropriate tolerances

Quality Control and Measurement Reports

After part production, all our products undergo rigorous quality control processes. Detailed quality control and measurement reports for each part are meticulously prepared and presented to you. When necessary, we obtain ultrasonic crack testing, liquid penetrant inspection, magnetic particle inspection, and/or radiographic inspection services from internationally accredited institutions to ensure product quality. This guarantees that all workpieces meet high-quality standards.

Industry Specific Solutions and Customer Focused Service

We provide tailored solutions for the needs of various sectors, including automotive, machinery manufacturing, medical devices, energy, aerospace, and defense industries. With our customer satisfaction-oriented approach, we support you at every stage of your projects and strive to achieve the best production results.

Material Types

Our diverse range of materials ensures we can meet various application requirements and provide high-quality products across different industries.

Cold Work Tool Steels

| 1.1730 | 1.2360 (X48CrMoV8-1-1) | 1.2436 (X210CrW12) |

| 1.2080 (X210Cr12) | 1.2363 (X100CrMoV5) | 1.2510 (100MnCrW4) |

| 1.2358 (60CrMoV18-5) | 1.2379 (X153CrMoV12) | 1.2550 (60WCrV8) |

| 1.2631 (X50CrMoW9-1-1) | 1.2746 (45NiCrMoV16-6) | 1.2767 (45NiCrMo16) (VNC4) |

Hot Work Tool Steels

| 1.2343 (X37CrMoV5-1) | 1.2365 (32CrMoV12-28) |

| 1.2344 (X40CrMoV5-1) | 1.2367 (X38CrMoV5-3) |

| 1.2345 (X50CrMoV5-1) | 1.2714 (55NiCrMoV7) |

Plastic Mold Steels

| 1.1730 | 1.2311 (40CrMnMo7) | 1.2738 (40CrMnNiMo8-6-4) |

| 1.2083 (X40Cr14) | 1.2312 (40CrMnMoS8-6) | 1.8550 (34CrAINi7) |

| 1.2085 (X33CrS16) | 1.2316 (X38CrMo16) Stainless Steel |

Yüksek Hız Çelikleri (HSS)

| 1.3207 | 1.3247 | 1.3243 | 1.3343 |

Nitrasyon Çelikleri

| 1.8519 (31CrMoV9) | 1.8550 (34CrAINi7) |

Diğer Çelikler

1.6523 (AISI 8620, 20NiCrMo2) Carburizing Steel

1.6582 (4340) Quenched and Tempered Steel

1.7225 (AISI 4140) Quenched and Tempered Steel

1.8159 (51CrV4) Spring Steel

SAE 1050 (C45) Carbon Steel

1.2083 (X40Cr14) | 1.4057 (X17CrNi16-2) | 1.4125 (X105CrMo17) |

1.2085 (X33CrS16) | 1.4112 (X90CrMoV18) | 1.4301 (X5CrNi18-10) (AISI 304) |

1.4034 (X46Cr13) | 1.4122 (X39CrMo17-1) | 1.4307 (X2CrNi18-9) (AISI 304L) |

1.4401-1.4436 (X5CrNiMo17-12-2) (AISI 316)

1.4404-1.4435 (X2CrNiMo18-14-3) (AISI 316L)

1.4542 (17-4 PH) (AISI 630)

1.4545-1.4548 (X5CrNiCuNb15-5) (15-5 PH)

1.4841 (X15CrNiSi25-20) (AISI 314)

EN AW-1050A | DIN 3.0255 | Al99,5

EN AW-2017A | DIN 3.1325 | AlCuMg1

EN AW-2024 | DIN 3.1355 | AlCuMg2

EN AW-5083 | DIN 3.3547 | AlMg4,5Mn

EN AW-5754 | DIN 3.3535 | AlMg3

EN AW-6060 | DIN 3.3206 | AlMgSi0,5

EN AW-6061 | DIN 3.3211 | AlMg1SiCu

EN AW-6082 | DIN 3.2315 | Als Si1MgMn

EN AW-7020 | DIN 3.4335 | AlZn4.5Mg1

EN AW-7022 | 3.4345 | AlZnMgCu0,5

EN AW-7075 | 3.4365 | AlZnMgCu1,5

CW614N | CuZn39Pb3 | EN12164 | ASTM C38500

CW710R | CuZn35Ni3Mn2AlPb | EN12163

CW617N | CuZn40Pb2 | ASTM C38000 EN12165

CW620N | CuZn41Pb1Al | ASTM C38000

CW024A | EN1652

CW004A | EN1172

CW021A | EN 13599

CW008A