Using the latest production technologies and our extensive supplier network, we offer superior solutions in sheet metal cutting processes. We provide services to meet all your cutting needs with CNC plasma cutting, CNC laser cutting, CNC water jet cutting, and CNC punch press (stamping) technologies.

CNC Cutting and Metal Processing Technologies

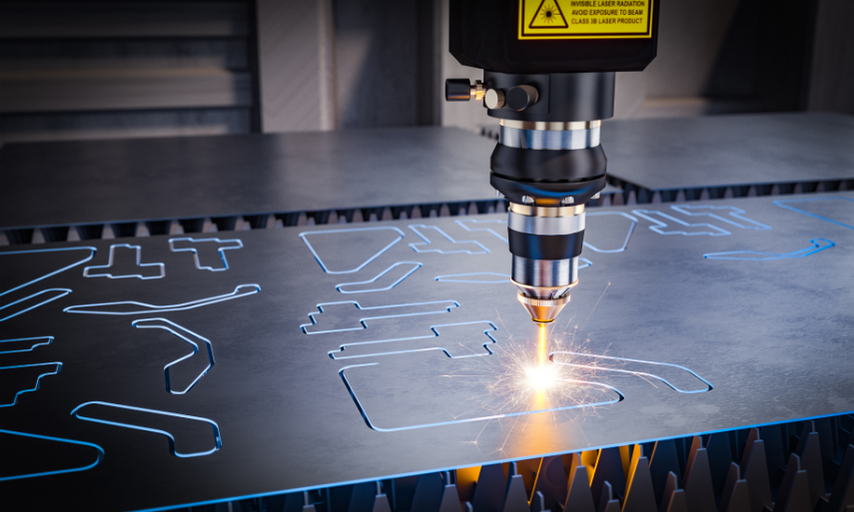

CNC laser cutting uses a high-intensity laser beam to perform fine and detailed cuts on sheet metals. It delivers excellent results in processing complex shapes. Laser cutting provides an economical, precise, and fast “cutting” solution on sheet metal. For this purpose, a CNC-controlled laser moves over the metal sheet panel. The high heat causes the metal to melt at specified points, resulting in separation along the cut edges. Common metal materials that can be cut with laser cutting include steel, aluminum, brass, and copper. However, depending on the material’s thickness, the laser cutting method is more suitable for thin to medium-thickness sheets.

CNC plasma cutting utilizes a high-temperature plasma arc to perform fast and precise cuts on conductive metals. Plasma cutting is a technique used for cutting metal sheets, employing plasma a gas that can melt at high temperatures. During the process, an electric arc is used to create the plasma. The electric arc heats the plasma gas, forming a high-temperature plasma jet. Plasma cutting is particularly suitable for cutting thick metal sheets and is commonly used for this purpose. The cutting thickness and tolerances are adjusted according to the properties of the material being cut to achieve optimal cutting results.

CNC water jet cutting is a technology that uses a high-pressure stream of water mixed with a special abrasive material to cut through various materials. In water jet cutting, the water pressure can typically reach 4000 bar or higher, and the water jet is accelerated through a specialized nozzle. In some cases, an abrasive material (often natural minerals such as almandine or garnet) is added to the water to enhance cutting performance.

Water jet cutting is capable of cutting a wide range of materials, including metal, glass, ceramic, stone, composite materials, and plastic. It generally has the capability to cut materials with thicknesses ranging from 0.1 mm to 200 mm, depending on the type of material and the power of the water jet system.

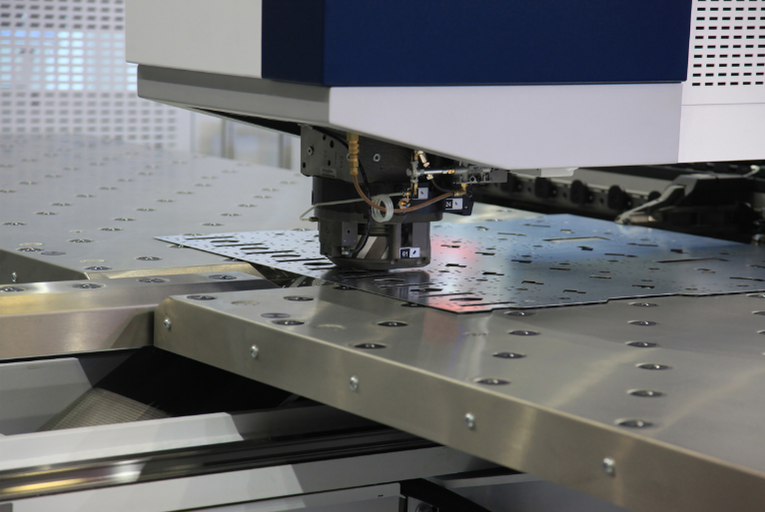

CNC punch press technology uses various punch tools to perform fast and efficient cuts, providing high speed and productivity, especially in mass production. It is used to punch, shape, or cut metal sheets through CNC-controlled processes, ensuring quick and efficient operations. Punch presses are typically integrated with automatic feeding and extraction systems, which enhance productivity. In addition to metal sheets, CNC punch presses can also be used on plastic and some composite materials. This technology is particularly preferred for high-volume and mass production. It is ideal for applications requiring precise holes, complex shapes, or repetitive punching operations.