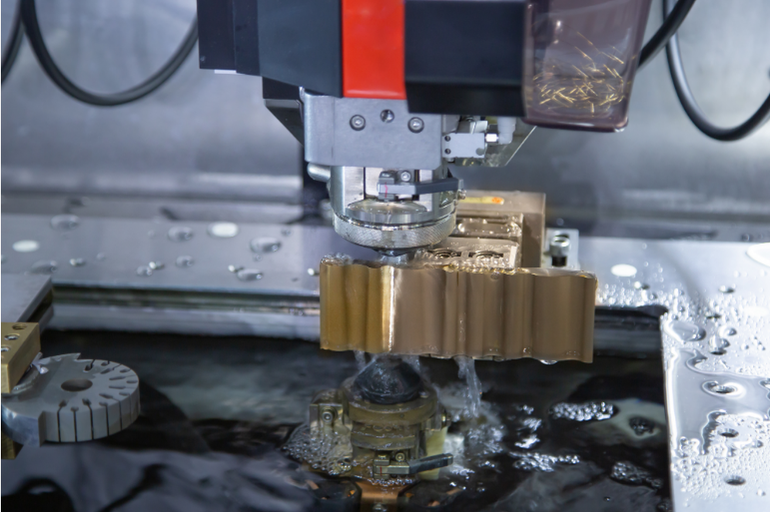

At Obersan Machinery Engineering Software Foreign Trade and Industry Limited Company, we offer comprehensive solutions in the field of advanced manufacturing technologies. In collaboration with our partnered manufacturers, we utilize Electrical Discharge Machining (EDM) technology to produce complex molds and parts tailored to your needs.

Advantages of EDM Technology

Electrical Discharge Machining (EDM) is an ideal solution for the production of parts that require high precision and complexity. This technology, which relies on the principle of eroding metal surfaces using electrical sparks, enables the production of many precision molds.

Precision: EDM provides micron-level precision, making it possible to machine parts with the finest details perfectly.

Complex Geometries: It simplifies the production of complex and intricate geometries that are difficult to machine with traditional methods.

High Surface Quality: Parts machined with EDM have smooth and high-quality surfaces, minimizing the need for subsequent processing.

Wide Range of Materials: EDM delivers effective results on a broad range of materials, including hard metals, heat-resistant alloys, and complex composites.

At Obersan Machinery Engineering Software Foreign Trade and Industry Limited Company, we offer tailored solutions to meet the specific needs of our customers across various sectors:

Mold Manufacturing: Production of high-precision injection molds, forging molds, and other specialized molds.

Part Production: Manufacturing of complex and detailed components, providing services from prototyping to mass production.

Customized Solutions: Developing project-specific production solutions based on the unique requirements of our customers.